Wet Motor HIGRA

The pursuit of energy efficiency, durability, and reliable operation has driven the advancement of technologies applied to pumping and power generation. In this context, HIGRA stands out as a pioneer in the development and application of the wet motor, an innovative solution that eliminates the use of oil, reduces thermal losses, and elevates performance across multiple applications.

This technology is present in equipment such as the renowned HIGRA Amphibious Pump, which combines versatility and robustness for different stages of the water cycle.

In this article, you will learn about the key technical characteristics and advantages of HIGRA’s wet motor technology, as well as practical applications in sectors such as sanitation, industry, agriculture, and clean energy generation.

Technical Characteristics of the Wet Motor

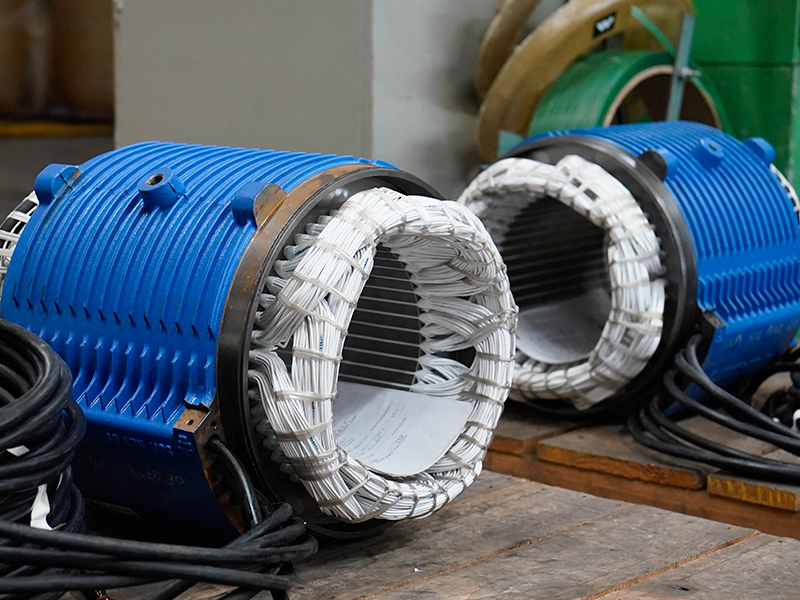

The wet motor, operating with water inside its housing, is an advanced electromechanical solution in which the motor’s main components — stator, rotor, and bearings — operate fully immersed in clean water. This configuration is designed to provide direct cooling and efficient lubrication without the need for external heat exchangers, forced ventilation, or lubricating oil.

Water circulates freely inside the motor casing, absorbing heat generated during operation and allowing constant thermal exchange with the pump body. This ensures thermal stability even under continuous operation.

The structure of the wet motor requires hermetic sealing and the use of high-performance insulating materials on the stator windings, such as dielectric-insulated copper wires suitable for full immersion. The sliding bearings are lubricated by the same internal water, reducing friction and significantly increasing the lifespan of moving components.

This integration of cooling and lubrication into a single working fluid simplifies maintenance, eliminates additional components, and increases operational reliability.

From a sustainability perspective, the use of water as the internal fluid directly contributes to energy efficiency. Direct cooling reduces thermal losses and prevents premature component wear, allowing the motor to operate within its optimal efficiency range with lower power consumption.

This feature is particularly advantageous in critical applications such as sanitation, urban drainage, and raw water intake, where continuous performance and low operating cost are essential.

By adopting the wet motor, HIGRA reinforces its commitment to sustainable, robust, and technologically superior solutions.

Wet Motor vs. Traditional Motor: Which Is the Better Choice?

When comparing the wet motor to a traditional electric motor (dry or oil-filled), it is possible to identify significant differences that directly impact the efficiency, durability, and operational sustainability of pumping systems.

| Criterion | Wet Motor (HIGRA) | Traditional Electric Motor |

| Cooling | Direct, with internal water circulation | Indirect, via forced ventilation or external exchanger |

| Lubrication | Provided by water, no oil needed | Requires lubricating oil |

| Environmental risk | Zero risk of leakage, clean operation | Risk of oil leakage in case of failure |

| Noise level | Very low, no external fans required | Higher, especially with external cooling fans |

| Energy efficiency | High, with reduced thermal loss and stable performance | Lower, due to cooling inefficiencies |

| Maintenance | Simplified, fewer components, lower wear | Frequent and more complex, especially oil-related |

| Durability | High, resistant to humid/aggressive environments | Reduced lifespan in harsh conditions |

| Sustainability | Superior, no contaminating fluids and lower energy use | Limited, uses oil and increases environmental impact |

Choosing HIGRA’s wet motor technology represents a significant evolution over traditional models. In addition to being more efficient and quieter, the wet motor is environmentally safe and ideal for continuous-duty applications that require reliability with the lowest possible operating cost — such as amphibious pumps, submersible pumps, and hydroturbines.

Advantages of Using Pumps with Wet Motors

The wet motor used in HIGRA amphibious pumps is a smart and efficient solution for applications requiring high performance, reliability, and low operational cost. Unlike conventional motors, this technology operates fully immersed in the pumped fluid, delivering direct benefits in energy efficiency, durability, and maintenance.

Below are the main technical advantages, with real examples across HIGRA’s served markets:

1. Higher Energy Efficiency

Direct cooling prevents thermal losses and reduces electrical consumption — especially valuable in large-scale center pivot irrigation systems operating continuously.

2. Continuous Lubrication and Reduced Wear

Immersion enables constant self-lubrication of components, increasing lifespan — essential in floating intake systems for industrial water supply.

3. Reduced Clogging and Low Maintenance

The hydraulic design minimizes blockage even in waters with suspended solids — ideal for lake water intake for industrial cooling systems.

4. Robustness and Durability

Efficient cooling reduces thermal stress — especially useful in rural water supply stations exposed to dust and temperature variation.

5. High Reliability in Critical Applications

Stable operation ensures continuity — crucial in industrial recirculation systems where downtime impacts production.

6. Oil-Free Operation: Clean and Safe

No lubricating oil means zero contamination risk, simplifying environmental licensing in potable and agricultural water intake.

7. Silent Operation

Immersion and no forced ventilation result in extremely low noise — ideal for urban stations and research facilities.

HIGRA Equipment with Wet Motor Technology

HIGRA leads the market in wet motor innovation for pumping, aeration, and energy generation systems.

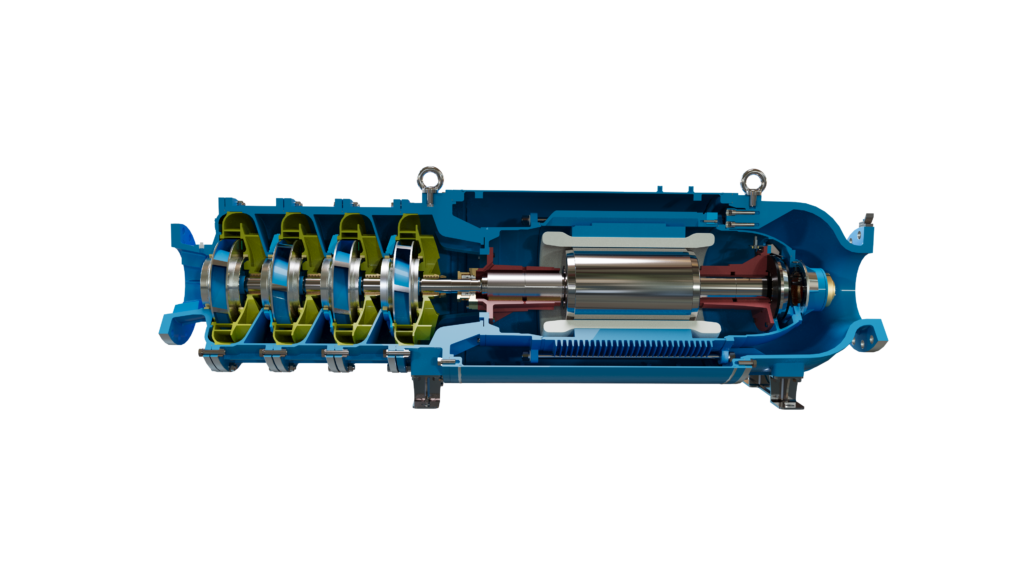

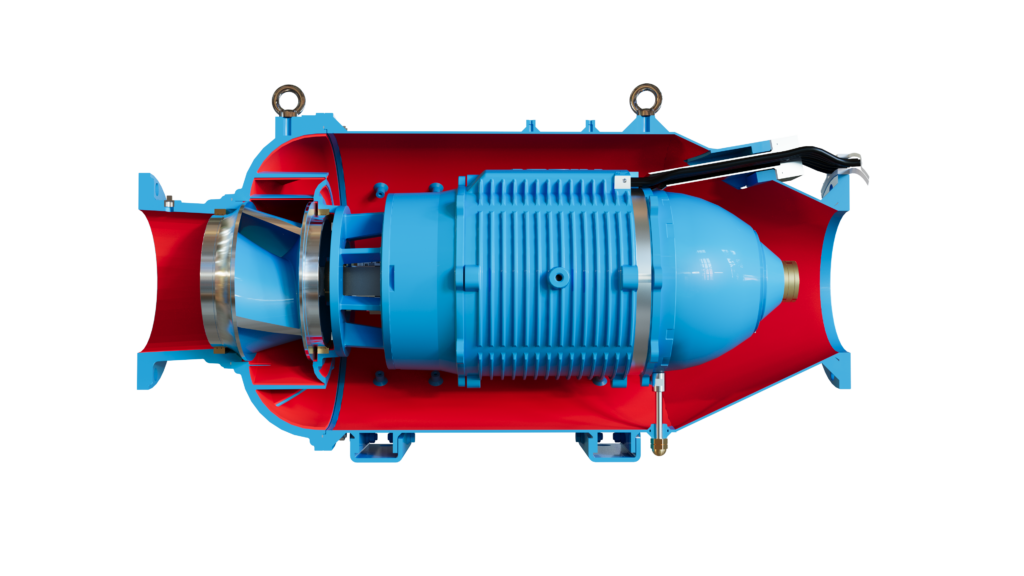

The HIGRA Amphibious Pump works both submersed and in open air, adapting to water level variations with high reliability — ideal for floating intakes, irrigation, industrial processes, and mobile pumping units.

HIGRA Submersible Pumps are built for continuous operation in demanding environments, combining corrosion resistance with high hydraulic performance — suitable for fixed water intake systems in industry, agriculture, and high-volume supply.

Amphibious Hydroturbines (TGA) use the wet generator concept to convert hydraulic energy into clean electricity, taking advantage of pressure drops and available flow — delivering sustainability with financial return.

In wastewater treatment, HIGRA submersible aerators and the new Ciclone surface-submersible aerator ensure efficient and reliable oxygenation.

If you are looking for performance, reliability, and sustainability, HIGRA’s wet motor technology is the right choice

Visit www.higra.com.br and discover how our solutions can transform your project.