SABESP Replaces Reducer Valves with HIGRA Turbogenerators

HIGRA’s commitment to energy efficiency can be seen in all the projects and actions the company undertakes. The technology embedded in the pumps and turbogenerators we develop and manufacture allows this equipment to operate at a high level of energy efficiency.

This is a distinguishing feature of our products which means that HIGRA technology is used in the most varied applications on the market. One of the uses we can mention is the replacement of pressure reducing valves with Amphibious Turbogenerators (TGAs).

Among the first companies to adopt this process is SABESP, the concessionaire responsible for supplying drinking water to cities in the state of São Paulo.

In this article, we’ll look in detail at how this replacement process took place and what benefits the upgrades to the pressurization lines brought to the company.

Pressure reducing valves: what they are and what they do

Pressure Reducing Valves (PRVs) are essential devices in water distribution systems, controlling and regulating pressure within supply networks. In hydraulic systems, water pressure can vary significantly due to factors such as topographical unevenness, variations in demand and distribution network configurations. Without proper control, this excessive pressure can cause leaks, pipe breaks and water waste.

The role of VRPs is precisely to prevent these problems by ensuring that the water pressure remains within a safe and suitable limit for consumption. They operate by reducing the water pressure from a higher level to a predetermined level, protecting the integrity of the network and improving the efficiency of the system.

Despite their widespread use, pressure reducing valves have an important limitation: they dissipate excess pressure by transforming hydraulic energy into heat, without using any energy. This feature has prompted the search for more efficient solutions that, in addition to controlling pressure, convert this dissipated energy into electricity, adding value to the process.

That’s where turbogenerators come in!

What are Turbogenerators?

As mentioned above, when applied to hydraulic systems, VRPs end up dissipating excess pressure by converting it into heat. Turbogenerators, on the other hand, use this excess energy to generate electricity.

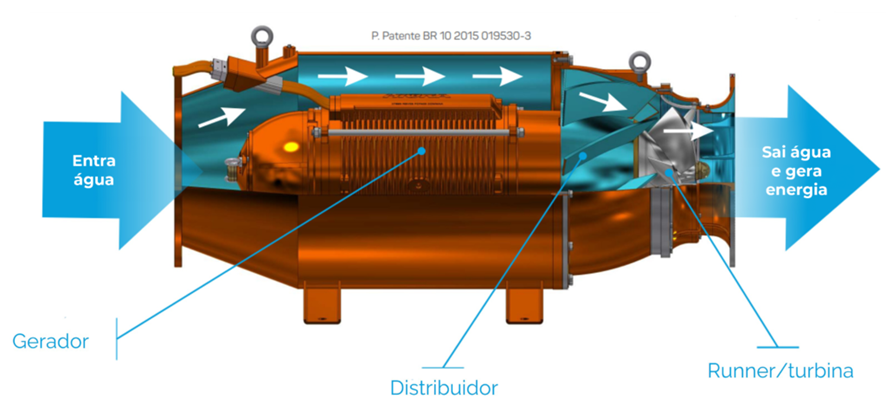

Turbogenerators work by converting hydraulic energy into mechanical energy and then into electrical energy. Pressurized water from a reservoir or forced conduit moves the turbine blades, converting hydraulic energy into mechanical rotation of the shaft.

This shaft is coupled to an electric generator, which transforms mechanical energy into electricity through electromagnetic induction. The energy generated can be used locally or integrated into the electricity grid, depending on the system’s needs.

In addition to harnessing energy, the equipment performs the same pressure control function as conventional valves, guaranteeing the safety of the supply network without wasting resources.

This differential makes the technology especially advantageous for sanitation utilities such as SABESP, which are looking to reduce operating costs and improve the sustainability of their operations.

Amphibious turbogenerators: discover HIGRA’s proprietary technology

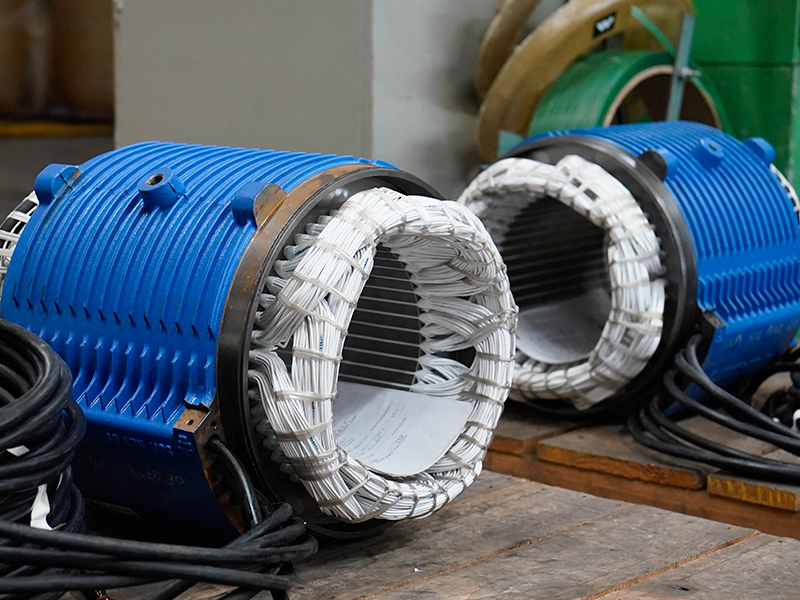

The Amphibious Turbogenerators (TGAs) developed and patented by HIGRA are integrated power generation units that combine a turbine and a submerged oil-free generator, capable of operating in different water flow conditions. Designed to replace VRPs in water supply and waterfall systems, TGAs are designed using fluid dynamics (CFD) simulation tools to optimize their geometry and maximize performance.

The turbine is sized according to the operating characteristics of each application, guaranteeing high efficiency in the conversion of potential energy into electrical energy.

The submerged electric generator is of the wet type and meets the NSF/ANSI 61 international standard for compatibility to operate with drinking water and uses the fluid passing through the machine itself to cool the equipment. This integrated design provides robust monoblock performance and offers ideal conditions for continuous and safe operation, with very low maintenance, high durability and low noise levels.

Operation is based on a turbine, which is driven by the flow of water at a certain pressure upstream. This turbine, connected to a generator, converts mechanical energy into electrical energy. The energy generated can be used to power the pumping and water treatment systems themselves, reducing energy consumption from the electricity grid.

If the energy generated is greater than the unit’s consumption, it can be injected into the grid, generating energy credits in the form of distributed generation.

Replacing VRPs with TGAs at SABESP

The use of new technologies, such as the HIGRA Amphibious Turbogenerators, allows innovative distributed generation models to emerge. Possible applications include the ability of small and medium-sized industries to use the hydraulic potential available in their operations to generate part of the energy they consume. This reduces operating costs and dependence on the conventional electricity grid.

This type of application already exists in Brazil and is in full operation at SABESP, one of the country’s largest sanitation utilities. HIGRA has installed 10 distributed generation systems, the UCHAs (Usina Compacta de Hidrogeração Anfíbia), which use the company’s TGAs, at the entrance to SABESP’s reservoirs. In total, they have 1.44 MW of installed power, enough to supply 5,000 homes every month.

A case study based on these applications demonstrates the implementation of TGAs to replace two pressure reducing valves (PRVs) in an 800 mm (DN800) diameter pipeline, controlling the water distribution pressure in a supply system. Operational data includes:

- Inlet pressure: 40 to 50 meters of water column (mca);

- Pressure required for distribution: between 24 and 26 mca;

- Average daytime flow: 450 liters per second (l/s), with a daily supply of approximately 16 hours (from 5 a.m. to 9 p.m.);

- Available hydraulic power: between 65 and 110 kW;

- Expected generation power: 40 to 75 kWh.

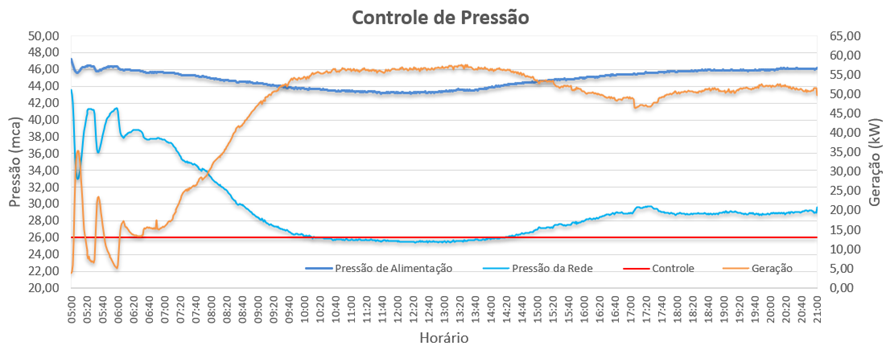

Graph 1 shows operating data during a typical operating day, illustrating the behavior of the distribution network pressure according to the control value and power generation.

The results obtained after 26 months of operation were as follows:

- Automated pressure control: The system operated efficiently, completely replacing the functionality of two VRPs and maintaining adequate distribution pressure;

- Energy use: The TGA took advantage of the hydraulic energy available, generating an average of 50 kWh, with peaks of up to 72 kWh during periods of high demand;

- Energy efficiency: The performance was 79% of the available energy converted into useful electricity;

- Cumulative generation: During the period of operation, the system generated 612,730 kWh;

- Noise: Operation was quiet, meeting local standards for residential areas, with noise emissions below 50 dB;

- Operational redundancy: The system has a backup device (duplicate), guaranteeing continuity of operation in the event of a failure.

High performance and energy efficiency with HIGRA Amphibious Turbogenerators

Amphibious Turbogenerators are a viable and efficient solution for replacing pressure reducing valves in water supply systems, with clear advantages in terms of energy generation, sustainability and automation. The technology, developed by HIGRA, has demonstrated high performance in practical applications, as seen in the case study presented.

With a performance of 79% of the energy generated over the potential energy available and the possibility of complete automation of pressure control, the TGA has emerged as a promising alternative for the future of renewable energy in hydraulic systems.

Want to know more about HIGRA’s Amphibious Turbogenerators? Fill in the form below and speak to one of our experts.