Energy improvement in the COPASA Cataguases/MG pumping system, Brazil

The irresponsible use of natural resources has made the human race hostage to its own mistakes. In particular, the public water supply, which until a few years ago was made up of clean sources collected from hillsides and brought to communities by the action of gravity, now depends almost entirely on pumping (Eletrobras 2005). Faced with this scenario, the emergence of options for use that reduce energy costs, among other costs, are important for the good service of sanitation companies in Brazil and around the world.

The stages involved in a water supply system generate major interventions based on complex engineering works and, in order to continue to grow and develop at the current rate, humanity must plan its development based on concerns about the binomial of water and energy (UN, 2017; GOŁAŚ; ZARĘBSKA; NOSEK, 2019). Studies estimate that around 3% of the world’s electricity consumption is used in water supply systems, 90% of which comes from the motor-pump sets in pumping stations, both for raw water and for pumping treated water (TSUTIYA, 2001; GOMES, 2004; WATERGY, 2009; SARBU, 2016).

Replacing motor-pump sets with high-performance equipment is one of the practices most used by utility operators. The efficiency of this equipment is a parameter that indicates its ability to convert electrical energy absorbed from the network into mechanical energy and then into hydraulic energy. The lower the losses, the higher the machine’s efficiency and, consequently, the lower the amount of energy needed to perform a given job.

Reducing electricity consumption through energy efficiency is directly linked to the electric motors that make up motor-pump sets. However, the term “hydro-energy efficiency” adds strength to the improvement of systems since, in addition to the search for better performing motors, it also encourages the use of pumps capable of achieving hydraulic outputs that are more consistent with demand. In other words, hydro-energy efficiency seeks solutions capable of reducing the cost of electricity and also promoting the achievement of higher flow rates and pressures by means of lower-powered equipment installed in pumping stations.

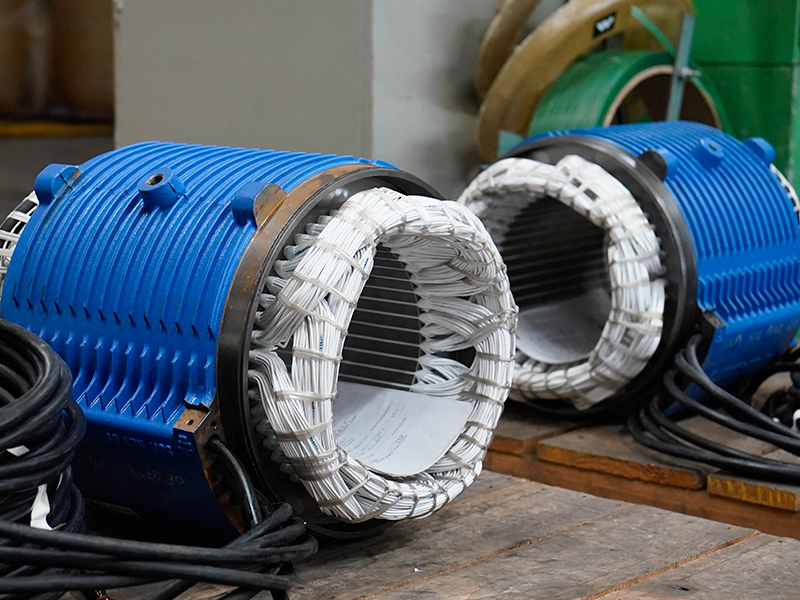

Amphibious motor pump sets are a solution designed to fill the existing market gap in terms of the effective application of hydro-energy efficiency. Thanks to their ability to operate both in and out of the water and the monobloc concept, the entire volume of the pumped fluid passes through the motor, guaranteeing excellent thermal exchange, which is one of their most important features, helping to increase energy efficiency. The versatility with which this equipment can be installed allows it to operate in extreme water situations, resulting in significant reductions in environmental impacts, electricity costs and maintenance costs.

In view of this, this article will evaluate the hydro-energy efficiency of COPASA’s pumping station in Cataguases, after replacing the horizontal axis equipment with amphibious motor-pump sets, focusing on elucidating the technical, economic and socio-environmental peculiarities of amphibious technology in this application.

Read the full article, download the event e-book: https://issuu.com/aprh/docs/15ca_programa

Download the full article here: https://drive.google.com/file/d/1zHRD81OfH9KeDOf71WLf4JI397crangr/view?usp=sharing

Download the full article: https://drive.google.com/file/d/1zHRD81OfH9KeDOf71WLf4JI397crangr/view?usp=sharing