Generation of Electric Power Through Amphibious Turbogenerators in Water Supply Systems: An Alternative to Pressure Reducing Valves (PRV)

In traditional water supply systems, Pressure Reducing Valves (PRVs) are used to regulate pressure in distribution networks by dissipating excess energy without utilizing it. Replacing these valves with Amphibious Turbogenerators (ATGs) offers an innovative solution by converting this wasted energy into electricity. The technology developed by HIGRA, in addition to being sustainable, provides installation flexibility and automation in pressure control, making it an efficient and effective alternative.

Technology of Amphibious Turbogenerators (TGA)

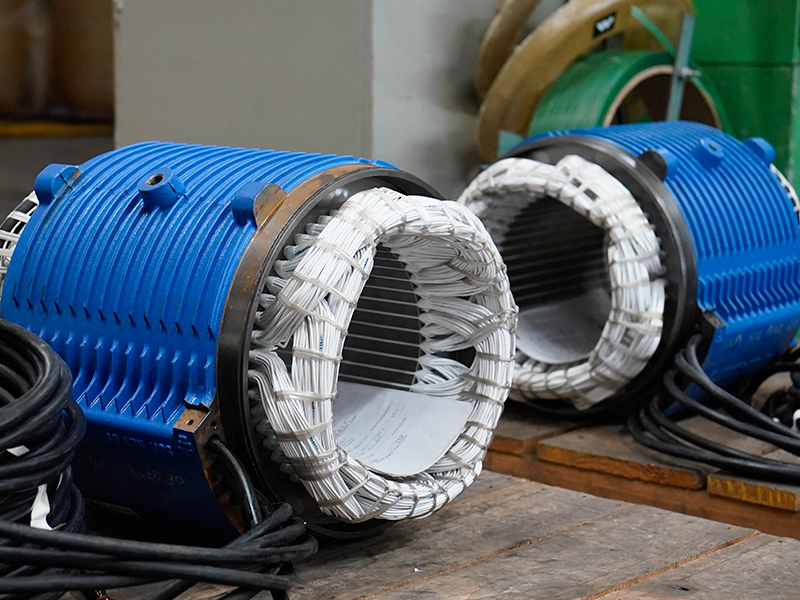

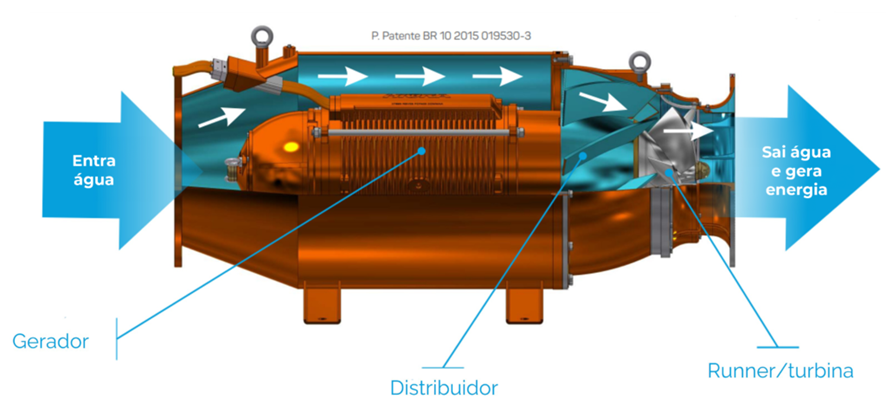

The Amphibious Turbogenerators (ATGs) developed and patented by HIGRA (Figure 1) are integrated energy generation devices that combine a turbine and an oil-free submerged generator, capable of operating under various water flow conditions. Designed to replace PRVs in water supply systems and harness the energy of waterfalls, TGAs are optimized using Computational Fluid Dynamics (CFD) simulation tools to enhance their geometry and maximize performance. The turbine is sized according to the operational characteristics of each application, ensuring high efficiency in converting potential energy into electrical energy.

The submerged “wet type” generator complies with the international standard NSF/ANSI 61 for compatibility to operate with drinking water, using the same fluid passing through the machine to cool the equipment. This integrated design provides a robust, monoblock-style performance, offering optimal conditions for continuous and safe operation with minimal maintenance, high durability, and low noise levels.

The operation is based on a turbine driven by the flow of water at a certain pressure upstream. This turbine, connected to a generator, converts mechanical energy into electrical energy. The generated energy can be used to power the water pumping and treatment systems themselves, reducing energy consumption from the electrical grid. If the generated energy exceeds the unit’s consumption, it can be fed back into the grid, generating energy credits within the distributed generation model.

Figure 1 – Amphibious Turbogenerator with a partial cross-sectional view to show how the water flow goes through the machine, exchanging heat, flowing through the distributor, and reaching the hydraulic turbine.

Electrical System and Automation

The power generation system with the turbogenerator in the sanitation sector also includes a regenerative frequency inverter of low voltage (which can be 220V AC, 380V AC, 440V AC, or another), responsible for varying the rotation of the equipment, enabling pressure control and ensuring the quality of the generated electricity that is injected into the connected circuit.

The solution includes automation that centralizes all the variables involved in the system, used at various points and crucial for control. The control system developed to maintain constant pressure in the water distribution network primarily uses the pressure variable of the network, along with other auxiliary variables for the correct operation of the turbogenerator.

Pressure control in the distribution network is achieved through the pressure reduction generated by the turbogenerator, which is developed and sized for the operating point with a certain operational range. Since the water flow in the supply network varies with consumption, the control system adjusts the turbogenerator’s rotation to match and maintain the desired pressure, which can either be a fixed value or operator-selected if necessary.

One of the concerns in water distribution networks is hydraulic transients. To address this, the turbogenerator’s automation uses PID control to prevent sudden changes in operation and ensure hydraulic stability.

Benefits of Implementation

Replacing PRVs with Amphibious Turbogenerators offers several technical and environmental benefits, such as:

- Clean energy generation: The energy that was previously dissipated as heat in the pressure-reducing valves is recovered and converted into electricity.

- Reduction in operational costs: The generated energy can be used to power water supply operations, reducing reliance on external energy sources.

- Sustainability: Implementing this technology contributes to reducing CO2 emissions, as energy generation is clean and free from polluting gases.

- Ease of integration: The turbogenerators can be installed in existing piping systems, utilizing the current infrastructure without the need for major modifications.

- Cost reduction: The electricity generated can be used directly by the water supply system or, if generation exceeds the unit’s consumption, can be injected into the power grid to generate energy credits, lowering operational costs.

- Versatility: TGAs can be installed in various configurations, both submerged and non-submerged areas, and in different types of hydraulic systems, such as water distribution networks and spillways in dams.

- Automation and remote control: The system offers automated pressure distribution control, with remote operation, improving operational efficiency.

Case Study: Replacement of PRVs in DN800 Water Conduit

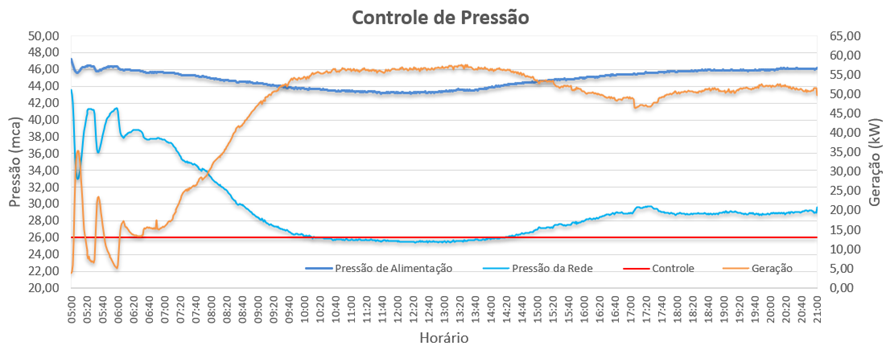

A real case study conducted at SABESP, the water operator in São Paulo, demonstrates the implementation of an TGA (Amphibious Turbogenerator) replacing two Pressure Reducing Valves (PRVs) in a DN800 (800 mm diameter) water conduit, controlling the water distribution pressure in a supply system. The operational data includes:

- Inlet pressure: 40 to 50 meters of water column (mca).

- Required distribution pressure: between 24 and 26 mca.

- Average daily flow: 450 liters per second (l/s), with daily operation of approximately 16 hours (from 5:00 AM to 9:00 PM).

- Available hydraulic power: Between 65 and 110 kW.

- Expected power generation: From 40 to 75 kWh.

Graph 1 shows operational data from a typical day of operation, illustrating the pressure behavior in the distribution network according to the control value and the energy generation.

Graph 1 – Distribution network pressure control, showing the supply pressure, network pressure, control value, and energy generation.

Figure 2 – Pressure control house showing the two water distribution lines with the use of pressure reducing valves (PRVs).

The results obtained after 26 months of operation were as follows:

- Automated pressure control: The system operated efficiently, fully replacing the functionality of two PRVs while maintaining the proper distribution pressure.

- Energy recovery: The TGA harnessed the available hydraulic energy, generating an average of 50 kWh, with peaks of up to 72 kWh during higher demand periods.

- Energy efficiency: The performance was 79% of the available energy converted into useful electricity.

- Accumulated generation: During the operational period, the system generated 612,730 kWh.

- Noise: The operation was silent, meeting local regulations for residential areas, with noise emissions below 50 dB.

- Operational redundancy: The system includes a backup device (duplication), ensuring continuous operation in case of failure.

Figure 3 – Installation of the Amphibious Compact Hydrogeneration Plant (UCHA) in series and upstream of the PRVs.

Conclusions

Conclusions

Amphibious Turbogenerators present a viable and efficient solution to replace pressure reducing valves in water supply systems, with clear advantages in terms of energy generation, sustainability, and automation. The technology, developed by HIGRA, has shown high performance in practical applications, as demonstrated in the case study presented. With a performance of 79% of the energy generated from the available potential energy and the possibility of full automation of pressure control, the TGA emerges as a promising alternative for the future of renewable energy in hydraulic systems.

Despite the benefits, the implementation of Amphibious Turbogenerators presents some challenges. The main barrier is related to the initial installation cost and the need for a detailed study to determine the technical feasibility of each system, as the amount of energy generated depends on water flow characteristics, such as flow rate and pressure, which can vary throughout the day and seasonally with water supply.

Additionally, the financial return of this technology is directly linked to the amount of energy that can be recovered and the availability of economic and regulatory incentives for the adoption of clean technologies.

Authors:

Greco Tusset de Moura – Mechanical Production Engineer and Technical Director at HIGRA

Gustavo Fischborn Pohren – Electrical Engineer and Technical Manager at HIGRA