Monoblock, Coupling-Free Pump: The Structural Advantage of HIGRA Amphibious Pumps Compared to Conventional Centrifugal Models

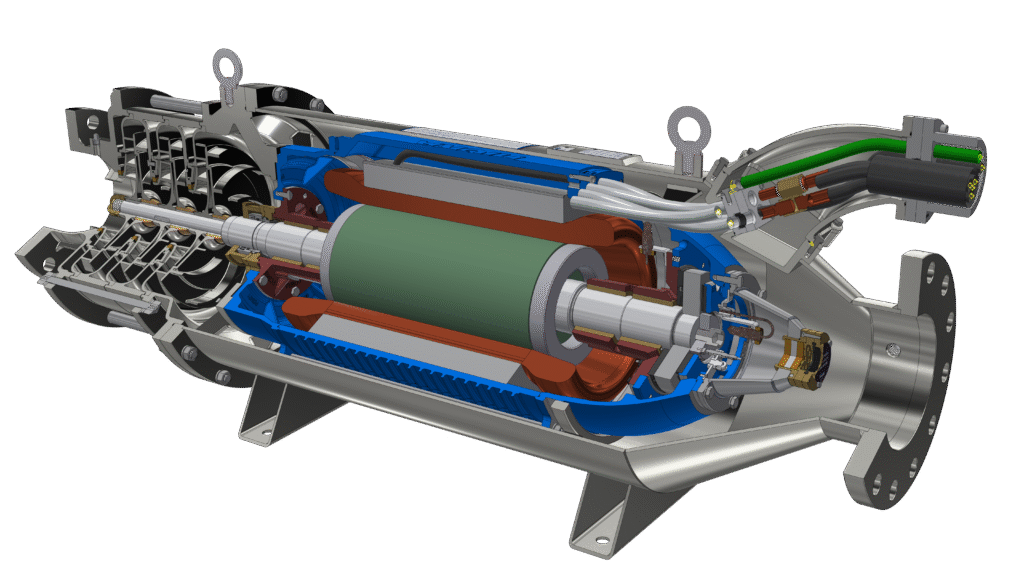

In the world of pumping systems—where reliability and robustness are non-negotiable—HIGRA Amphibious Pumps stand out for more than just hydraulic performance. Their true differentiation lies in their monoblock structure. By integrating motor and pump into a single body, the HIGRA monoblock pump eliminates misalignment between components, one of the leading causes of failure in traditional systems.

More than an engineering choice, the monoblock concept allows HIGRA to maximize performance, reduce downtime, and simplify field operations. These characteristics are essential across multiple scenarios—from industrial areas affected by flooding to raw water intake stations and pressurized distribution networks that ensure water supply to communities.

In this article, you’ll understand how the monoblock design directly impacts the efficiency and durability of HIGRA Amphibious Pumps. Join us on this journey and discover why this technical solution translates into less maintenance, greater robustness, and increased operational safety for your pumping system.

What Is a Monoblock Pump?

Unlike conventional centrifugal pumps—which require coupling between the motor and pump using independent shafts—the monoblock pump integrates everything into a single assembly. Motor and pump share the same shaft, the same body, and the same structure, eliminating the need for mechanical synchronization between two separate pieces of equipment.

This technological approach directly removes one of the main causes of failures in pumping systems: misalignment.

Why Is Misalignment a Problem?

In traditional equipment, any assembly error, foundation settlement, or external vibration can create misalignment between motor and pump, generating consequences such as:

Premature Wear of Bearings and Seals

When motor and pump are not perfectly aligned, the rotating shaft experiences abnormal lateral forces. This places stress on bearings and mechanical seals, forcing them to operate outside design tolerances. The result: accelerated wear, leaks, increased temperature, and, in many cases, premature failure—leading to frequent maintenance stops.

Impact: higher maintenance costs and greater risk of operational failure during critical moments.

Excessive Vibration and Noise

Misalignment creates shaft imbalance, causing continuous mechanical vibration during operation. These vibrations increase noise and propagate through the base structure and nearby equipment.

Impacto: comprometimento da integridade estrutural da fundação e redução da vida útil de todo o sistema de bombeamento.

Higher Energy Consumption

A misaligned system requires more effort from the motor to overcome friction and maintain shaft rotation, resulting in increased electrical consumption, overheating, and reduced hydraulic efficiency.

Impact: higher energy costs, reduced efficiency, and a larger carbon footprint.

Unplanned Maintenance Downtime

Misalignment accelerates internal component degradation and can lead to sudden failures. In critical systems—such as drainage stations or water intake units—this may interrupt supply, increase flooding risks, or cause environmental issues.

Impact: emergency shutdowns, high corrective costs, and potential non-compliance with operational contracts.

In traditional pumping systems made of separately coupled motor and pump assemblies, this constant risk of misalignment demands frequent inspections, realignment after each intervention, and ultimately increases operational costs.

HIGRA Monoblock Pumps with a Single Shaft

HIGRA Amphibious Pumps adopt the monoblock concept with excellence. Designed to operate both submerged and dry, they combine high hydraulic performance with a highly reliable mechanical assembly.

Key advantages of the HIGRA monoblock system include:

- Zero need for shaft alignment

- Simplified and fast assembly

- Lower risk of vibration-induced failures

- Reduced installation time and cost

- More robustness and safety in severe environments

This configuration is especially valuable in urban drainage, mining, water utilities, and irrigation—segments where system reliability is critical and unplanned downtime can result in significant losses.

Additionally, because they are engineered to operate in difficult-access locations and even under heavy solid accumulation, HIGRA Amphibious Pumps deliver high performance with minimal intervention.

Learn more about their drainage capacity in the article Efficiency and Versatility of Amphibious Pumps in Urban Stormwater Drainage.

Monoblock Pumps and Wet Motor Technology for High Performance

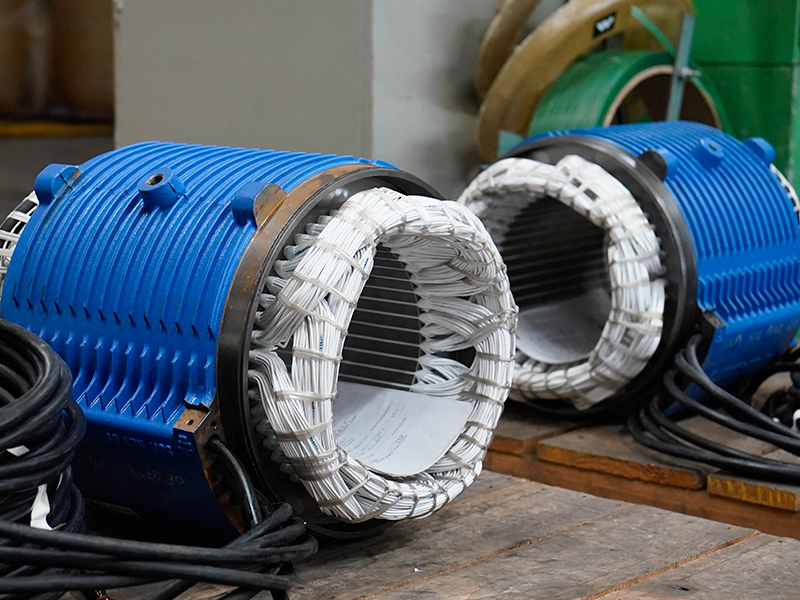

The monoblock structure becomes even more powerful when combined with another exclusive HIGRA innovation: the wet motor. Unlike conventional electric motors, the wet motor operates completely submerged, with water circulating inside its structure for cooling and lubrication. This eliminates the need for external ventilation, greased bearings, or additional cooling systems—cutting down failure points.

By integrating this motor directly into the pump body, HIGRA creates a robust, compact, hermetically sealed unit—ideal for harsh environments with high debris loads. There are no exposed transmissions, pulleys, couplings, or external moving parts. Everything is protected and engineered to withstand demanding operation for long periods with minimal intervention.

Read more about wet motor technology in the article What Is a Wet Motor, available on our blog.

The synergy between the wet motor and the monoblock design is the result of decades of research and development at HIGRA—and it brings a real competitive advantage. The result is a highly reliable, energy-efficient piece of equipment with an extended lifecycle, ideal for smart and sustainable water-cycle solutions.

Monoblock Is Not Just a Detail—It’s a Technical Breakthrough

Adopting the monoblock concept in HIGRA amphibious pumps represents a true evolution in pump design. It’s a solution that puts into practice the core pillars of the brand: innovation, efficiency, and durability. Want to learn more about how HIGRA technology can transform your pumping system? Click the button below and speak with one of our specialists.