Amphibious pumps

Technology developed by HIGRA represents innovation and power efficiency in pumping applications such as sanitation, harvesting, mining, water recirculation in wastewater treatment and irrigation systems. With easy and versatile installation, it works inside and out of water. Its unique design, with flanged axial suction, centrifugal impeller and integrated motor, offers superior performance at any condition.

Concept and Features

The amphibious pumping concept is HIGRA’s pioneer unique development. The ability of a same equipment to operate inside and out of water, without any changes, is a result of the pump design. The fluid flow is admitted by the flanged axial suction, passes through a centrifugal impeller and alongside the motor. This system assures excellent thermal exchange, low noise emission (less than 60Db), versatile installation, low maintenance and high-power efficiency.

The company’s activities are based on sustainability, from product creation to its installation. Using state-of-the-art software, field situations are simulated to achieve the best performance results. All pumps go through a rigid battery of tests at HIGRA’s Hydropower Test Laboratory to get real proof of performance.

The use of the amphibious pump concept in pumping stations is an alternative market for those looking for a higher Return on Investment and peace of mind.

Our Amphibious Pumps

Semi-Axial Pump

High Flow/Low Pressure

Flow rate: 1200 to 6000 m³/h

Power: 75 to 300 Hp

Pressure: up to 18 mH20

Single and Multi-Stage Mixed Pump | High Flow

Flow rate: 120 to 2500 m³/h

Power: 12 to 600 Hp

Pressure: up to 50 mH20

Single Stage Radial Pump | High Pressure

Flow rate: 15 to 2600 m³/h

Power: 10 to 750 Hp

Pressure: up to 80 mH20

Multi-Stage Radial Pump | High Pressure

Flow rate: 14 to 2000 m³/h

Power: 15 to 600 Hp

Pressure: up to 295 mH20

Solutions

- Ability to work at PPAs (Permanent Preservation Areas) without environmental impact

- Operation inside or out of water

- Easy installation in hard-to-reach places with varying water levels

- Lower maintenance cost with a long service life

- High hydropower efficiency, with up to 30% energy saving

- Versatility in applications due to the variety of pump pressures and flow rates

- Water-cooled mechanical and electrical system, with no need for lubricants/greases

- Low noise level that assures the professionals’ health and reduces labor liabilities

- Very low civil engineering costs due to the easy installation

- Better performance guaranteed by state-of-the-art software

Ways of Installation – HIGRA Amphibious Pumps

Submerged

Equipment totally submerged in the water. Ideal for any harvesting applications, such as irrigation, central pivot feeding, collection of river water for water treatment plants, raw water and others.

Partially Submerged

Pump partially submerged in water. Ideal for shallow water level applications. For being an amphibious equipment, it has the ability of free collection, just like when operating totally submersed.

Modulated Pumps

Combination of pumps summing flow rates and/or pressures. For being an amphibious equipment, it offers excellent drainage of high flow rates or discharge line pressurization.

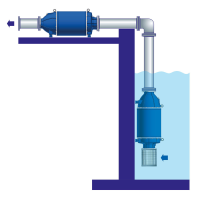

Suction

Type of installation that characterizes HIGRA pumps’ amphibianism, assuring the same efficiency when operating submersed, when respected the NPSH conditions. Ideal for any application that demands suction operation regimen

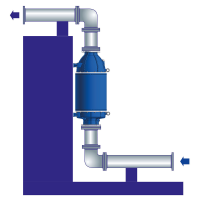

Booster

Pump connected to the pipeline to increase the pressure in a system. Compact and efficient solution for several systems.

Over Float

Pump submersed over floating structure. Ideal for areas with restriction of space or access, such as lakes and rivers. Easy relocation and minimal environmental impact.

Get in touch

HIGRA is innovation, technology and sustainability

We are passionate about solving problems in a sustainable way. Through our disruptive technologies, we look for making the world a better place to live.

We believe the world is full of abundant resources, but people don’t always have access to them. Part of our mission is to be a sustainable vehicle that provides access to these resources.

“The future doesn’t belong to us, but making it better is part of our present.”