Aerators

Reliable and sustainable solution for the treatment of urban and industrial effluents, offering high efficiency and homogenization. Essential for oxygenating aquatic ecosystems, our equipment uses water-lubricated radial bearings, guaranteeing not only sustainability and the preservation of natural resources, but also better engine performance.

Concept and Characteristics

HIGRA’s aerator lines are designed and manufactured in compliance with the main quality, environmental, health and safety standards. 100% of the materials are recyclable and have been created to meet the needs of the wastewater treatment market. The product’s operational advantages include low noise emission, excellent mixing coverage and high oxygen incorporation.

The innovative design of HIGRA equipment provides better hydro-energy efficiency, which leads to optimum savings in energy consumption. To create and continuously improve performance, HIGRA uses the most modern hydrodynamic simulation tools, always looking for the best cost-benefit ratio for the user.

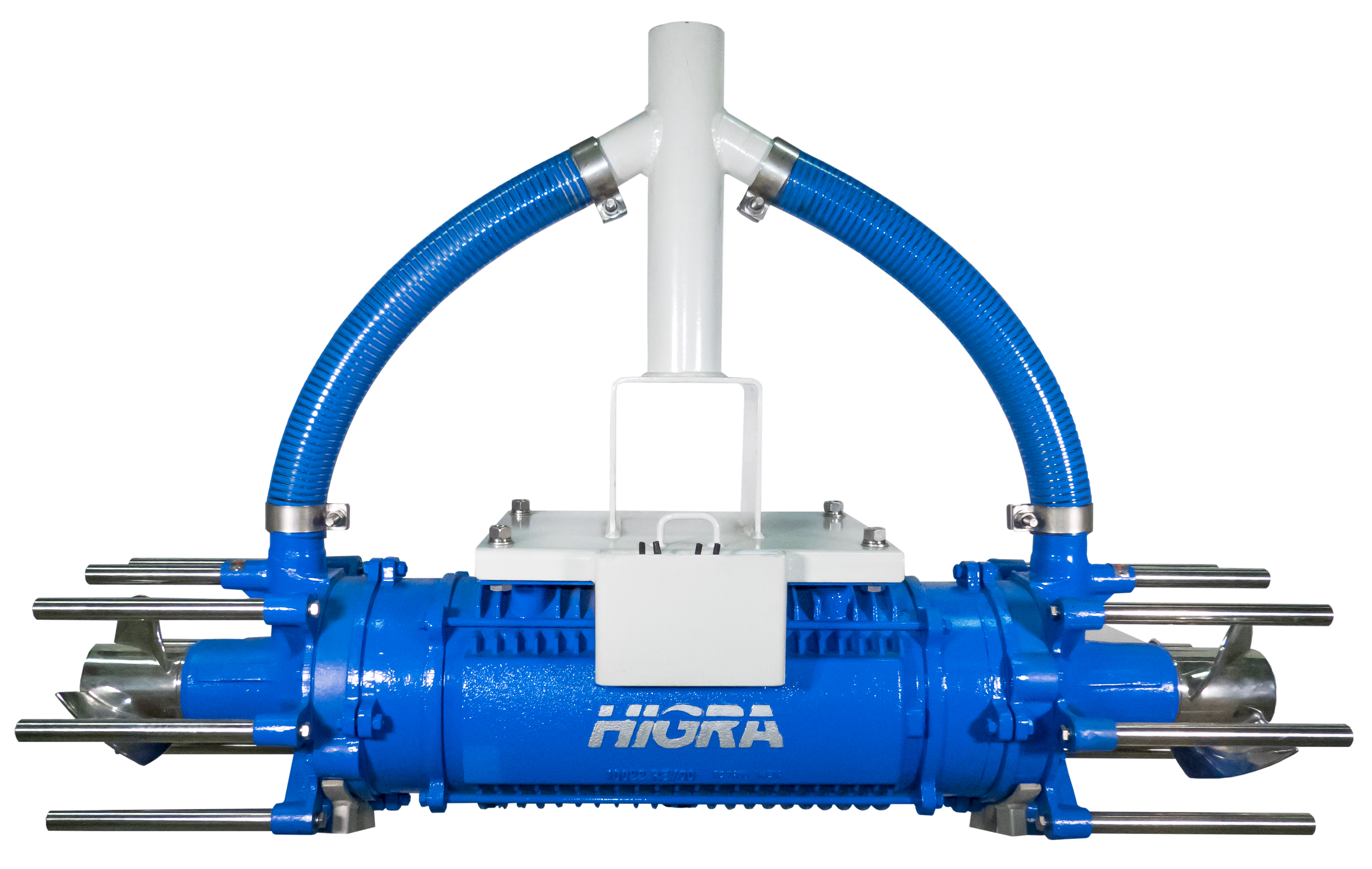

Surface Aerator Submerged Cyclone

Meet the Ciclone, the first submerged surface aerator on the market. Built in a monoblock structure with a floating flow director, the Ciclone offers greater mixing range and oxygen incorporation, guaranteeing superior performance in different applications.

Equipped with a 1750 RPM (4P) wet motor that complies with IEC85 and ABNT NBR IEC 60529:2005 standards, the Cyclone combines high technology with the traditional robustness of HIGRA equipment.

Its multi-directional aeration system, combined with a nodular cast iron body and high-performance impeller, ensures maximum energy efficiency and resistance.

It also has a height adjustment that can be adjusted to the level of the water blade, providing versatility and precise control in different scenarios.

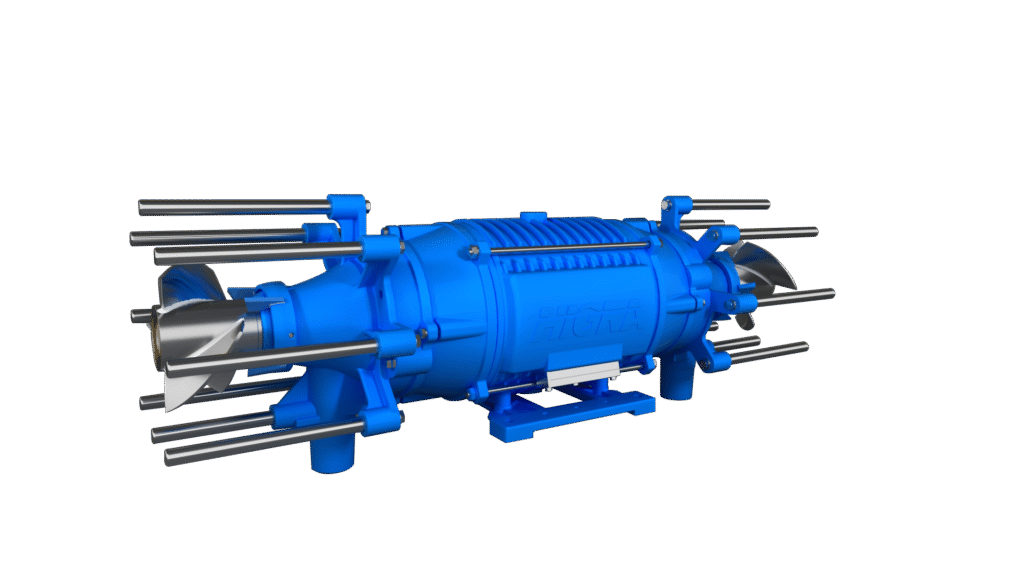

Tornado Submerged Aerator

The main advantage of the HIGRA Tornado Aerator is its ability to mix and oxygenate ponds and tanks of great depth, due to its tilting capacity.

With this inclination, the pumping flow forms a descending parabola, completely homogenizing the bottom of the treatment, achieving excellent oxygenation.

As the equipment is unidirectional, it can be distributed in different formats within the treatment plant, adapting to the geometry of the ponds and tanks, promoting complete mixing and oxygenation and fixing up to 55% of the oxygen sucked in.

The product can also be supplied in the angular directional rotary system, which allows movement of up to 160°.

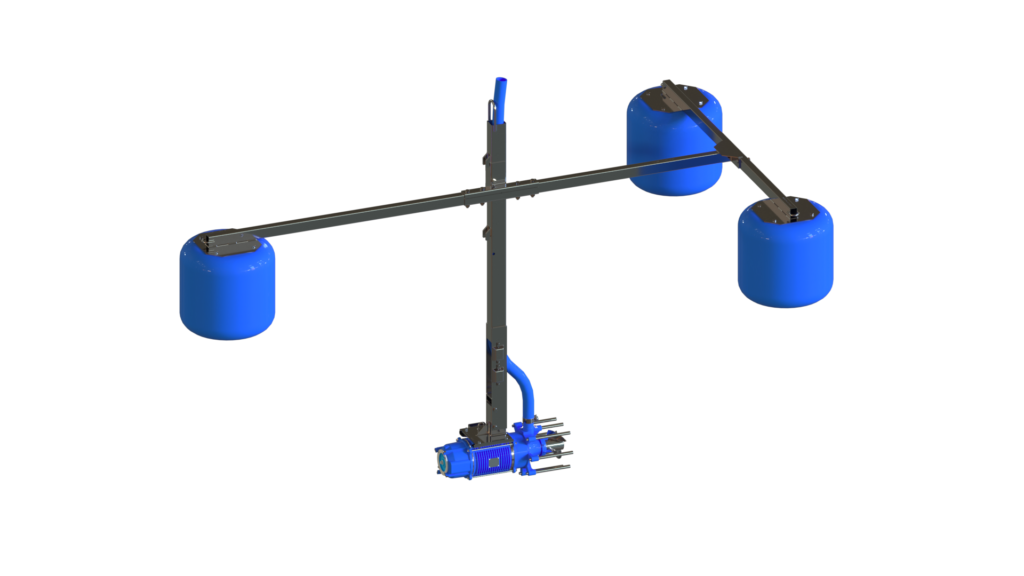

Tornado Biturbo Submerged Aerator

The Tornado Biturbo is ideal for treatment plants with tanks or lagoons that don’t require rotating or inclined equipment. With two propellers in opposite directions, it increases the transfer of oxygen and mixing.

Bidirectional pumping eliminates thrust and reduces the buoyancy structure. It offers high oxygenation capacity with a simple, low-cost structure.

The Tornado Biturbo also has a rotating version, which equalizes traction between propellers, making the set more compact and easier to install.

With 360° rotation, the aerator covers an area 45% more efficiently than conventional models. Continuous movement guarantees up to 80% fixation of the microbubbles sucked in.

Solutions

- High Hydro-Energy Efficiency

- Previously simulated projects via CFX

- Excellent mixing capacity

- Engineering active throughout the process

- High oxygen transfer rate

- 360° mixing and aeration radius

- Low energy consumption

- Compact and lightweight flotation frame

- Simple assembly and installation

- Good performance in deep tanks/ponds

- Low maintenance

Get in touch

HIGRA is innovation, technology and sustainability

We are a company passionate about solving problems in a sustainable way. Through our disruptive technologies, we seek to make the world a better place to live.

We believe that the world is full of abundant resources, but that people don’t always have access to them. Part of our mission is to be a sustainable vehicle that provides access to these resources.

“The future doesn’t belong to us, but making it better is part of our present.”